:+86 021-31170068

: www.shqhvalve.com

:sales@shqhvalve.com

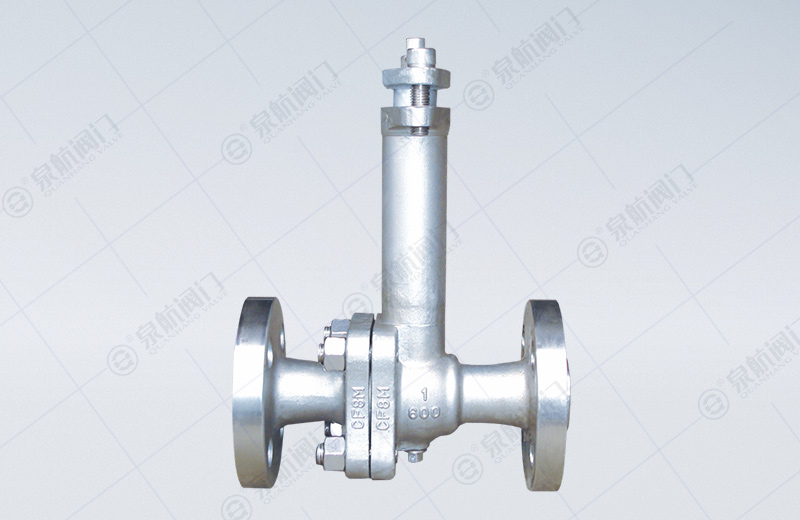

Cryogenic Ball Valve

Product overview

Cryogenic ball valve is mainly used in the ethylene device, such as liquefied natural gas chemical industry, the output of the cryogenic liquid medium such as ethylene, liquid oxygen and liquid hydrogen. This kind of media not only flammable and explosive, and when temperature gasification, gasification and volume expansion is hundreds of times.

Product Features

1. The material of pressure bearing parts can withstand the expansion, contraction and sealing structure caused by the change of medium temperature, and the structure of sealing parts will not produce permanent deformation when the temperature changes. When the valve parts are used under the working condition below - 100 ℃, the valve parts shall be subject to cryogenic treatment before finishing, that is, the parts shall be immersed in liquid nitrogen tank for cooling. When the temperature of the parts reaches - 192 ℃, the valve parts shall be kept for 1-2 h, and then the outside of the box shall be taken out for natural treatment to normal temperature, and then the valve parts shall be reheated for 2 times.

2. The valve cover adopts a long stiffened structure, which aims to protect the function of the stuffing box and keep the stuffing box far away from the low temperature to ensure the sealing effect of the packing. At the same time, it can also wrap the cold insulation material to prevent the loss of cold energy. The length of the long neck can be selected according to the temperature and the thickness of the cold insulation material. When the packing sealing effect decreases, grease can be added from the middle of the stuffing box to form an oil seal layer, which can reduce the differential pressure of the stuffing box and improve the sealing performance.

3. When the service temperature is lower than - 100 ℃, the valve stem material is treated by chromium plating or nitriding, which can improve the surface hardness of the valve stem and improve the reliability of the packing seal.

4. Low temperature ball valve has a structure to prevent abnormal pressure rise. Since the volume of cryogenic valve expands rapidly after medium gasification, the pressure will increase abnormally. When the pressure in the middle chamber of the valve rises, the middle chamber of the valve is connected with the inlet, or a pressure relief valve is installed at the inlet end of the valve to ensure the safe use of the valve.

5. The gasket used for low temperature ball valve has reliable sealing and recovery under normal temperature, low temperature state and temperature change.

Execution Standard

Design spec:GB/T 12237

Face to Face:GB/T 12221

Flange end:GB/T 9113

Test & check:GB/T 26480、GB/T 13927

Pressure-temp:GB/T 12224

Performance Parameter

Nominal diameter:DN15~250mm

Nominal Pressure:PN1.6~2.5MPa

Applicable media:Water, oil, steam, acid and other corrosive media

Applicable temperature:-196~29℃

Main materials:LCB、CF8